Featuring a few snippets from one of my latest co-authored papers on the use of digital technologies for lean and sustainable value chains. A few sections have been adapted to be presented as a blog post.

Suggested citation: Strazzullo, S., Cricelli, L., Troise, C. & Camilleri, M.A. (2024). Leveraging Industry 4.0 technologies for sustainable value chains: Raising awareness on digital transformation and responsible operations management, Sustainable Development, https://doi.org/10.1002/sd.3211

Abstract

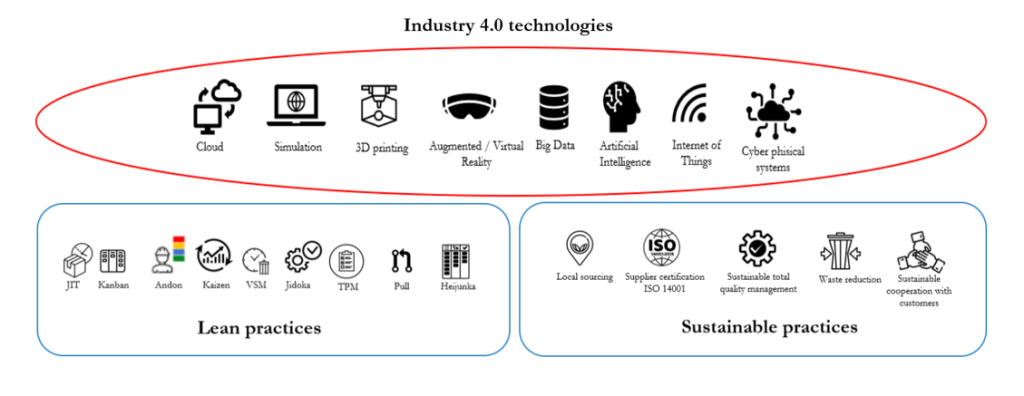

Practitioners, policy makers as well as scholars are increasingly focusing their attention on the promotion of sustainable practices that reduce the businesses’ impacts on the environment. In many cases, they are well aware that manufacturers and their suppliers are resorting to lean management processes and Industry 4.0 (I4.0) technologies such as big data, internet of things (IoT), and artificial intelligence (AI), among others, to implement sustainable production models in their operational processes. This research utilizes an inductive approach to better understand how I4.0 technologies could result in increased organizational performance in terms of resource efficiencies, quality assurance as well as in environmentally sustainable outcomes, in the context of the automotive industry. The findings shed light on the relationship between I4.0 technologies, sustainable and lean practices of automakers of combustion engines, hybrid models and/or electric vehicles (EVs). In conclusion, this contribution puts forward an original conceptual framework that clearly explains how practitioners can avail themselves of disruptive technologies to foster continuous improvements in their value chain.

Keywords: Industry 4.0, digital transformation, lean management, sustainable supply chain, responsible operations management, resource efficiencies.

Introduction

The manufacturing industries are characterized by their increased emphasis on the development of sustainable practices that are facilitated by digital technologies. Companies are under pressure from a wide range of stakeholders, including by regulatory institutions and by individual customers, among others (Wellbrock et al., 2020). In parallel, in recent years, most businesses have gradually introduced Industry 4.0 (I4.0) technologies in their manufacturing processes, as they shifted to smart factory models (Atif, 2023; Choi et al., 2022; Varriale et al., 2024). However, they cannot disregard their corporate responsibilities on economic, environmental and social aspects (Sunar & Swaminathan, 2022). Many researchers contend that sustainability behaviors ought to be integrated with I4.0 processes (Ghobakhloo, 2020), in order to enhance the effectiveness, efficiencies and economies of their Supply Chains (SC) (Núñez-Merino et al., 2020). To be competitive in this context, SCs are implementing lean management models to improve their operations.

The sustainability of SC is related to the notion of Lean Supply Chain Management (LSCM) that refers to the elimination of non-value-added activities in order to enhance the manufacturing firms’ performance (Centobelli et al., 2022; Núñez-Merino et al., 2020). The proponents of LSCM suggest that the generation of waste can be reduced through responsible management strategies (Deshpande & Swaminathan, 2020). Arguably, the minimization of externalities can ultimately affect all stakeholders of SCs, ranging from the business itself, its suppliers as well as its consumers (Khorasani et al., 2020). Notwithstanding, the stakeholders’ pressures on organizations has led them to change their operational approaches to comply with new environmental regulations and to respond to the growing demands of customers for sustainable products and services (Adomako et al., 2022; Camilleri et al., 2023).

As a result, many commentators are also raising awareness on the Sustainable Supply Chain Management (SSCM) concept (Sonar et al., 2022; Yadav et al., 2020). Very often, they claim that SSCM is an important organizational model that can increase corporate profits and boost market shares. The SSCM proposition is based on the reduction of risks from unwanted environmental impacts, thereby improving the overall efficiency of SCs (Negri et al., 2021). Previous contributions have clearly demonstrated how LSCM and SSCM are closely related to one another (Azevedo et al., 2017). More recent studies have deepened the link between the lean management paradigm and I4.0 (Oliveira-Dias et al., 2022; Tissir et al., 2022). The integration of these two concepts has led to the formulation of new definitions such as “Lean 4.0” and “Digital Lean Manufacturing”, among others.

Given the increased complexity of operations, many researchers debate that the introduction of lean practices may not be enough to address extant competitive pressures. Although lean management can improve the operational efficiencies of SCs and may add value to their organization, there is still scope for practitioners to continue ameliorating their extant processes. Lean initiatives are reaching a point where they are becoming common practice in different contexts. Many manufacturers are adopting them to reduce their costs. However, the success of lean production practices relies on the management’s strategic decisions and on operational changes they are willing to undertake. Arguably, both SSCM and LSCM are aimed at fostering more flexible, fast, customized, and transparent operations management in manufacturing and distribution systems. Some studies have already clarified how digital technologies can help practitioners to improve achieve these objectives (Ghobakhloo, 2020; Varriale et al., 2024).

Several academic studies have not considered the fact that SCs are becoming more technologically savvy. As technologies continue to evolve, they are transforming the modus operandi of many businesses. Today’s organizational processes are increasingly utilizing different types of innovative solutions. Undoubtedly, manufacturers ought to keep up with the latest advances in technology and with the changing market conditions. Besides, a number of firms are opting to outsource their manufacturing processes to low-cost developing countries. In this light, this research builds on theoretical underpinnings focused on the link between SSCM and LSCM. However, it differentiates itself from previous contributions, as it clarifies how these two paradigms can be connected to I4.0.

Notwithstanding, for the time being, there is still a lack of agreement among academia, policy makers and expert practitioners about what constitutes lean, sustainable systems in today’s manufacturing landscape. Although there a number of stakeholders who are already engaging in LSCM and SSCM practices to meet the new challenges and opportunities presented by I4.0 and the digital age, others are still lagging behind, or are considering SSCM and LSCM and digital technologies as silos, as they see no link between these approaches (Narkhede et al., 2024).

For example, at the time of writing, several automotive manufacturers claim that they are integrating lean and sustainable practices. Very often, they indicate that they utilize I4.0’s disruptive technologies. Yet, a number of academic commentators argue that some of these practitioners unsustainable manufacturing processes and waste management behaviors are contributing to the negative impacts to the degradation of the natural environment, thereby accelerating climate change (Liu & Kong, 2021; Sonar et al., 2022).

Lately, academic colleagues have sought to highlight the synergies between I4.0 technologies, lean management principles and sustainable practices (Centobelli et al., 2022; Cerchione, 2024). The majority of contributions provide a conceptual study of the potential relationship between I4.0, sustainable and lean SCs. However, to date, limited research have integrated lean SC, SSC and I4.0 technologies. This paper represents one of the first attempts to investigate the connection between SSCM, LSCM and I4.0 paradigms, in depth and breadth, in the context of the automotive industry. For the time being, there is still limited research that raises awareness on sustainable and lean supply chain systems that are benefiting from disruptive technologies (Cerchione, 2024; Guo et al., 2022). Hence, this contribution addresses this knowledge gap. Specifically, it seeks to explore these research questions (RQs):

RQ1: Which I4.0 technologies and to what extent are they supporting the manufacturing businesses in their adoption of sustainable and lean management practices?

RQ2: How is the automotive industry’s SC benefiting from the utilization of disruptive technologies, as well as from sustainable and lean management practices?

The underlying goal of this contribution is to raise awareness on how manufacturing businesses including automotive corporations utilize I4.0 technologies, implement lean management as well as sustainable practices to improve their SCs performance. An inductive approach is utilized to address the above RQs. Rich qualitative data were captured through semi-structured interviews with expert practitioners who hold relevant experience in planning, organizing, leading and controlling responsible operations management initiatives in the automotive industry, and who are already deploying a wide array of I4.0 technologies in their manufacturing processes.

The researchers adopt a hermeneutic approach to outline the thematic analysis (TA) of their interpretative findings. They identify the main intersections between SSCM, LSCM and I4.0 paradigms. Moreover, they provide a conceptual framework that clearly explicates how practitioners can avail themselves of I4.0 technologies to advance sustainable and lean management practices in different phases of the supply chain, including in the sourcing of materials, inventory control, manufacturing processes, logistics/distribution of products, as well as in their after sales services.

Literature review

Companies can create value when they have the competences, capabilities and resources to create products. (Khan et al., 2016). They ought to be flexible and responsive to their customers’ needs, particularly in a competitive environment, like the automotive industry. Indeed, customers tend to evaluate the companies based on the products they sell and on their unique selling propositions (Kumar Singh & Modgil, 2020). The lean management principles can therefore help manufacturers to implement the philosophy of continuous improvements in their operational performance (Marodin et al. 2016), in order to add value to their customers, and to increase the likelihood of repeat business (Liker, 2004; Papadopoulou & Özbayrak, 2005).

Such ongoing improvements are not only relevant during production (e.g. within the automotive workshops) but may also be implemented throughout the entire SC, including in customer-facing environments (Cagliano et al., 2006). There are a number of lean management approaches that can be taken on board by different manufacturers including by automakers. Table 1 provides a list of lean practices (that could also be adopted within the automotive industry):

Table 1. A non-exhaustive list of lean management terms

| Lean Practices | Definitions | References |

| Andon | Andon is a quality control signaling system that provides notifications on issues relating to the maintenance of certain operational processes. An alert can be activated automatically through automated systems or manually by employees. As a result, Andon systems can pause production so that operational issues can be rectified. | (Saurin et al., 2011) |

| Heijunka | Heijunka is intended to improve operational flows by reducing the unevenness in production processes and by minimizing the chance of overburden. It can used to process orders according to fluctuations in demand, and to respond to changes by levelling production by volume or by type, thereby utilizing existing capacity in the best possible way. | (Nordin et al., 2010) |

| Jidoka | Jidoke refers to automated systems that are monitored and supervised by humans. It is used to improve the product quality and to prevent any malfunctions during manufacturing processes. | (Liker & Morgan, 2006) |

| Just in time (JIT) | A JIT system is an inventory management strategy that is based on forecasted demand. It aligns purchasing and procurement tasks with production schedules. Companies employ this lean strategy to increase their efficiency by reducing overproduction, unnecessary waiting times, excessive inventory, product defects and unwanted waste. JIT is evidenced when materials and goods are ordered, only when they are required. | (Mayr et al., 2018; Sanders et al., 2016) |

| Kaizen | Kaizen is a lean production management approach that promotes continuous improvements in manufacturing processes on a day-by-day basis. This notion is based on the idea that ongoing positive changes will gradually result in significant improvements in the long run. Organizations adopting Kaizen will motivate their employees to consistently boost their productivity, reduce waste, lower defects and to be accountable in their jobs. | (Valamede & Akkari, 2020) |

| Kanban | Kanban involves a scheduling system that can improve operational efficiencies in lean manufacturing environments. One of its main advantages is to limit the buildup of excess materials and resources at any point in time during operational processes. Practitioners ought to ensure that they are maintaining a predefined inventory level for production purposes. | (Valamede & Akkari, 2020) |

| Pull Production (PP) | PP is a lean management methodology that is intended to control production processes in order to limit overproduction, reduce surpluses and to minimize warehouse costs. PP can be used to determine the optimal quantity that should be produced. Production occurs when and where it is needed, according to demand. | (Sanders et al., 2017b) |

| Total Productive Maintenance (TPM) | TPM is a holistic maintenance approach that is used to improve operational efficiency and product quality, by eliminating failures and defects. Moreover, it promotes a safe working environment to prevent accidents from happening. It also aims to motivate employees to improve their job satisfaction, productivity and organizational performance | (Mayr et al., 2018; Valamede & Akkari 2020) |

| Value Stream Mapping (VSM) | VSM (is also known as material- and information-flow mapping) is a lean management method that involves the analysis of extant operations to better plan operational procedures, for the future. It is a visual tool that describes (in detail) all critical steps in specific manufacturing processes. | (De Raedemaecker et al., 2017; Wagner et al., 2017) |

Table 2 describes some of the most prevalent sustainability practices that are being employed in the automotive industry, as well as in other manufacturing contexts.

Table 2 Sustainable practices adopted by manufacturing businesses

| Sustainable Practices | Definitions | References |

| Sustainable Total Quality Management (STQM) | STQM is a management approach that relies on the participation of all members of staff to create long-term value to their organization and to society at large, by considering the triple bottom line objectives in terms of profit, people and planet. | (Yadav et al., 2020) |

| Local sourcing | Local sourcing is related to the procurement of products, resources or materials from producers and suppliers located in close proximity to the manufacturing facility, rather than acquiring them from international sources. This approach encourages companies to purchase their requirements from local suppliers to reduce costs and to minimize their impact on the environment. | (Zailani et al., 2015) |

| Sustainable cooperation with customers | “Sustainable cooperation with customers” involves the businesses’ engagement activities with customers. Organizations can increase their customers’ awareness about social responsible issues and environmentally sustainable initiatives. | (Eltayeb et al., 2011; Purba Rao, 2018) |

| Sustainable employee engagement | “Sustainable employee engagement” is associated with the organizations’ relationship with its employees. Employers are expected to treat their employees well with dignity and respect. It is in their interest to foster an organizational climate that rewards their hard in a commensurate manner. | (Robinson et al., 2003) |

| Supplier certification International Standards Organization’s (ISO’s) Environmental Management Standard (ISO14001) | ISO14001 is one of the most widely used environmental management standard. It encourages manufacturing practitioners to continuously improve their operations to minimize their impact on the environment. It clearly recommends that environmental management issues ought to be embedded within the organizations’ strategic planning processes and that business leaders should pledge their commitment to implement sustainable initiatives that are aimed to protect the environment and to mitigate climate change. | (Camilleri, 2022; Potoski & Prakash 2005) |

| Waste and emissions reductions | The “waste and emissions reductions” constitute one of the most important aspects of sustainable production. Manufacturing businesses ought to reduce the generation of externalities including the accumulation of waste and emissions resulting from their operations. They are expected to strictly comply with the relevant legislation to protect the environment and to prevent any detrimental effects from waste and emissions on eco systems. | (Vijayvargy & Agarwal, 2014) |

Table 3 sheds light on some of I4.0 technologies that are being employed within the automotive industry.

Table 3. I4.0 technologies that are utilized in the automotive industry

| I4.0 Technologies | Definitions | References |

| Three-Dimensional (3D) printing | 3D printing is based on additive technology that can create solid objects from computer-aided design (CAD) software, or via 3D models. | (Kamble et al. 2018) |

| Artificial Intelligence (AI) | AI is concerned with computers and machines that are capable of mimicking human reasoning, human learning and even human behaviors. Basically, it involves a set of machine learning and deep learning technologies that can be used to analyze, predict and forecast data, to categorize objects, to process natural language, to make recommendations, and to retrieve intelligent data retrieval. | (Chae and Goh 2020; Ghobakhloo 2020) |

| Augmented Reality (AR) | AR enables its users to view virtual content that comprises multiple sensory modalities that may include visual, vocal, haptic, olfactory, and other somatosensory stimuli in a real-world environment. | (Mayr et al., 2018; Rüßmann et al., 2015) |

| Big Data (BIG DATA) | BIG DATA refers to data sets that are too large or complex to be dealt with via conventional data processing software. Supposedly, big data software can rapidly handle large volumes as well as a variety of information. | (Swaminathan, 2018; Vaidya et al., 2018) |

| Blockchain | A blockchain is a distributed ledger technology that allows its users to track and store records (blocks). The blocks hold transactional data that are securely linked together via cryptographic hashes that are timestamped. Each block is linked to the other. | (Pun et al., 2021) |

| Cloud computing | Cloud computing refers to on-demand computer resources that can be utilized to share and store data in an agile and flexible manner, beyond company boundaries, through multiple locations. | (Tao & Qi 2019; Vaidya et al. 2018) |

| Cyber Physical Systems (CPSs) | CPSs are related to physical and software systems that are deeply intertwined to operate spatial and temporal scales. They are controlled and/or monitored by algorithms to interact with each other in ways that change with context. They exhibit multiple and distinct behavioral modalities. | (Adamides & Karacapilidis, 2020; Kamble et al., 2018; Wang et al., 2016) |

| Internet of Things (IoT) | IoT are physical objects (or groups of objects) with sensors that can enable them to process and exchange data with other devices and systems via the Internet or other communications networks. | (He & Xu, 2014) |

| Virtual simulation (VS) | VS refers to computational system-based modeling that relies on real-time data to mirror the physical world. Virtual models can include machines, products, and humans. A simulation provides a preliminary analysis of different processes (and phases) that make up the operational processes, thereby presenting performance estimates for production management. | (Li et al., 2018) |

Discussion

This research sought to examine the role of I4.0 technologies in supporting sustainable and lean initiatives in SCs. To this end, an inductive study involving a thematic analysis was conducted to answer the underlying RQs. Interestingly, the findings clearly indicate that utilization of I4.0 technologies are opening up new opportunities in the automotive industry. They confirm that carmakers are changing their modus operandi in terms of their procurement of resources, production practices, and of how they are servicing their customers. It shows that a myriad of digital technologies (including big data, simulation and IoT, among others) are facilitating the implementation of lean programs, thereby improving productivity outcomes, whilst decreasing operational costs.

Moreover, it reported that certain disruptive technologies can be utilized to create value to environmental sustainability in terms of waste minimization practices through recycling procedures, reductions in CO2 emissions, lower energy consumption levels, et cetera, thereby diminishing the businesses’ impact on the natural environments. This research noted that the automakers’ implementation of sustainable practices is not as conspicuous as that of their lean management practices, in the academic literature, even though most of them are increasingly producing sustainable vehicles including hybrids and EVs.

In addition, the findings indicate that there is still scope for manufacturing firms to avail themselves of I4.0 systems to consistently improve their operations in SCs. The results reported that big data can be used to pursue continuous improvements and Kaizen approaches to improve efficiencies, lower costs and reduce waste. They revealed that practitioners are collaborating with marketplace stakeholders and utilizing JIT systems to responsibly source materials and resources when they are required. Moreover, they found that organizations are availing themselves of Andon and Jidoka automated systems to monitor and control different manufacturing processes in the supply chain, to ensure the smooth running of operations.

Theoretical implications

This contribution convergences Industry 4.0 and responsible supply chain practices with lean management approaches. It raises awareness on how manufacturers including those operating in the automotive industry, can improve their quality standards through specific tools (e.g. Andon and Jidoka) and techniques (like Kaizen and Kanban, among others), to enhance their efficiencies, reduce costs and eliminate non-value-added activities. It explains that there is scope for sustainable businesses to invest in disruptive technologies and long-term cultural change to achieve continuous improvements in their supply chains. It clarifies that the intersection of LSCM, SSCM and I4.0 can potentially revolutionize operations management, as practitioners can benefit from digital technologies like real-time data, cloud, AI, CPS, blockchain technologies to consistently ameliorate their production systems in a sustainable manner.

Arguably, businesses can avail themselves of big data analytics, simulations and digital twins, to anticipate demand fluctuations, optimize inventory levels, reduce lead times. These data-driven innovations enable them to proactively respond to changing market conditions and disruptions, identify potential disruptions early, and to mitigate risks. In addition, they could invest in Blockchain digital ledger technologies to trace materials, components and products to ensure responsible sourcing of goods, increase the sustainability of their operations and reduce the businesses’ environmental impact.

Alternatively, they can utilize CPS systems to automate tasks, improve quality control and to reduce errors from their production processes. These approaches would probably lead to better resource utilization, waste management and circular economy approaches like recyclability, reusability and repairability of assets to extend their lifecycles. Hence, practitioners can align I4.0 paradigm with the lean principles of pull production and just-in-time systems as well as with sustainable supply chain management. For the time being, few researchers have delved into these promising areas of study. Even fewer contributions have investigated these issues in the automotive industry context. This contribution addresses these knowledge gaps in academia. It advances a comprehensive theoretical framework that clearly sheds light on the link between I4.0, strategic lean management approaches and sustainability outcomes including improved resource efficiencies and reduced externalities, among others.

Managerial implications

Regarding the implications for practitioners, this contribution raises awareness on the importance of using technologies to improve the efficiency, economy and effectiveness of SCs, in a sustainable manner. The interpretative findings of this research identified a set of I4.0 technologies and practices that can improve the performance of SCs in the automotive industry. Among the various I4.0 technologies, the informants identified: IoT, simulation, cloud, and big data as some of the most effective tools to enhance the organizational performance of manufacturing businesses. Generally, they indicated that their companies were relying on insights from big data to continuously improve their operations. Evidently, they captured data as they tracked different processes of their operations, in real time. Subsequently, the gathered data is analyzed to discover any areas for improvement. For example, big data could reveal that modifications may be required if certain processes and procedures are not adding value to the company, or if they are translating to operational inefficiencies and/or to unwanted waste.

Most interviewees showed that they utilized simulations, cloud systems and IoT to adopt JIT, Kaizen, Jidoka, local sourcing, and waste reduction initiatives. They explained how they benefitted from these technologies to optimize their operations, in terms their procurement of materials, as well as in other areas including in distribution and marketing activities. For instance, the findings clearly reported that IoT can support the implementation of local sourcing of resources, by minimizing the vulnerabilities and logistical costs associated with long SCs and could improve efficiency by providing valuable information about machine health, including predictive maintenance requirements, at logistics centers or warehouses.

This research reported that these tools enabled practitioners to monitor the operational performance in all phases of their SC, including from the selection of suppliers until the delivery of after-sales services to their valued customers. As mentioned above, the utilization of systems such as big data, analytics and the use of cloud technologies for data storage are adding value to the companies’ SC. Data-driven technologies facilitate the exchange of information between marketplace stakeholders (e.g. with intermediaries). They can foster lean management approaches by increasing throughput, addressing bottlenecks, streamlining processes and by reducing delays, resulting in improved productivity, operational efficiencies, better time management and in lower risks for SCs.

Macroenvironmental factors, including political, economic, social, and technological issues could also impact on the businesses’ I4.0 digital transformation and implementation of sustainable operations management. The transition towards a zero-waste model could prove to be a costly, long-term investment for businesses including those operating in the automotive industry. Although financial investments in new technologies could possibly improve operational efficiencies (Camilleri, 2019), there could still be a low demand for them, particularly if I4.0 systems require behavioural changes by their users.

The full list of references are included in the last part of this open-access article: https://doi.org/10.1002/sd.3211

This research is also available via Researchgate: https://www.researchgate.net/publication/384191949_Leveraging_Industry_40_technologies_for_sustainable_value_chains_Raising_awareness_on_digital_transformation_and_responsible_operations_management

You must be logged in to post a comment.