The following content was drawn from one of my academic articles published through the International Journal of Hospitality Management. It has been adapted for a blog post.

Stakeholders including the regulatory authorities, among others, are increasingly encouraging hospitality businesses to publish information about their environmental, social and governance (ESG) activities. In many cases, they are already preparing ESG disclosures that shed light on their sustainable production and consumption policies and practices.

The environmental dimension

Generally, many hospitality chains are already monitoring the usage of their energy, water, raw materials and other resources, to minimize their running costs. For example, their restaurants could turn off certain appliances when not in use, invest in efficient lighting, appliances, cooking methods, as well as in water conservation practices (Madanaguli et al., 2022). In addition, they could generate their energy from renewable sources. Other aspects that are related to ESG’s ‘E’ dimension include environmental protection measures, sustainable sourcing of food items and their components (as the responsible procurement of items from local suppliers would reduce their environmental impact), as well as waste minimization efforts before, during and after food consumption, among others laudable practices (Elkhwesky, 2022). Hospitality businesses may avail themselves of food waste tracking systems to optimize their production and consumption activities, and to identify areas for improvement (Okumus et al., 2020). Such systems could help them reduce food scraps that will probably end up in landfills, if they recycle them into compost, that may be used for local farming or landscaping.

Very often, they gather and hold records about their recycling efforts as well as on their generated waste and emissions that can ultimately affect biodiversity and eco-systems including climate change, water and marine resources (Klaura et al., 2023). If this is the case, their captured data can be utilized to identify inefficiencies in their restaurants and to better understand how sustainable practices (like the ones mentioned in the above text) could reduce their costs as well as their overall financial performance. Moreover, it enables them to be in a good position to disclose information about their sustainability credentials.

Restauranteurs should prioritize purchasing from local sources to support the domestic economy and reduce transportation emissions. Food and beverage preparers could utilize seasonal menus to ensure that the dishes they serve and/or their ingredients are fresh and in-season. This reasoning is congruent with the farm-to-fork or farm-to-table initiatives adopted by various hotels and restaurants (Bux and Amicarelli, 2023). Frequently, hospitality businesses are opting for organic certified products and food components, to reduce the environmental impact associated with conventional agricultural practices. In a similar vein, many practitioners are investing in ant-based and insect-based items as more consumers are recognizing their nutrition benefits (Motoki et al., 2022). A number of colleagues are recognizing that such protein foods would result in lower externalities on the environment.

In this day and age, it is imperative that food and beverage service providers utilize sustainable food items in their menus. They are pressured by stakeholders to use eco-friendly packaging made from recycled, biodegradable, compostable, and/or reusable materials for food delivery and takeaway services as opposed to single-use plastic waste that pollute the natural environment. In sum, the hospitality businesses’ environmental responsibilities comprise sustainable sourcing of food items, sound inventory management, innovative food preparation practices, responsible consumption of food, and the use of eco-friendly packaging, to minimize their environmental footprint, and contribute to broader sustainability goals.

The social dimension

Most practitioners are taking into account non-financial information about hospitality businesses’ labor practices related to their own employees as well as to other workers employed by organizations in the value chain (including distributors, suppliers, subcontractors, et cetera) (Bullock et al., 2024). Report preparers may usually gather information about the conditions of employment of human resources, training and development records, health and safety measures, work life balance initiatives, living wage policies as well as on issues related to equal opportunities, diversity and inclusion in their workplace environment. A number of contributions reported that there is scope for hospitality owner-managers to delegate responsibilities to employees to enhance their morale and job satisfaction (Camilleri, 2022, Gewinner, 2020). Frequently, they indicated that it is in their businesses’ interest to provide regular training and development opportunities on sustainable practices like food hygiene and safety, meal portion control as well as on food waste management, among others (Okumus, 2020). Notwithstanding, they are expected to communicate about their active engagement with suppliers. It is within their responsibility to ensure that they treat their marketplace stakeholders in a fair manner. They are expected to forge long lasting, mutual relationships with trustworthy suppliers and partners, who are recognized as responsible employers by stakeholders in society.

Hospitality businesses ought to be encouraged to source food items from local suppliers to promote community well-being. They should prioritize suppliers that are renowned for their dependability, responsible human resources management and environmental sustainability practices. Working closely with reliable suppliers could help improve the efficient sourcing of products and may result in timely delivery of fresh items (Vaughan, 2024). The practitioners’ engagement with suppliers would increase their chances of receiving food products and ingredients in an optimal condition, to reduce the likelihood of spoilage and of overstocking their inventories.

In addition, the social dimension may usually involve aspects related to the businesses’ engagement with customers as well as with societal stakeholders. Hospitality practitioners can promote their sustainable procurement and food production practices with customers. The food and beverage businesses’ communications and corporate disclosures about their sustainable credentials can influence their consumers’ behaviors. They could even induce their patrons to reduce food loss and waste in their households.

Report preparers could make reference to responsible marketing practices. They can raise awareness about their transparent pricing and on how they avoid deceptive or misleading tactics (Aschemann-Witzel et al., 2023). They might communicate about their commitment to protect their consumers’ personal data. It this case, practitioners may reveal that they are using secure systems to prevent data breaches and unauthorized access to information. In addition, they could publicize the provision of accessible facilities for disabled patrons. Furthermore, they may shed light on their cultural sensitivity, as well as on their engagement with local communities through food donation programs to philanthropic and charitable institutions, among other socially responsible behaviors. Their proactive collaboration with local communities, NGOs, and other stakeholders can help them achieve the sustainable development goal related to the responsible production and consumption (of food) to reduce the accumulation of waste originating from their operations (UNEP, n.d.). Conversely, they may decide to monetize their waste resources by utilize sharing economy platforms and functional mobile apps to sell surplus/excessive food to consumers, at reduced prices.

In a nutshell, the hospitality practitioners’ social responsibility aspects cover aspects related to their engagement with responsible suppliers, employees, customers and with the community at large. Restauranteurs are expected to communicate about their organizations’ responsible food production and consumption practices with a wide array of stakeholders. Their corporate reporting can add value to their business in terms of increased profits, as they benefit from an improved brand image and corporate reputation, among other positive outcomes.

The governance dimension

Listed hotel chains are frequently disseminating content about their corporate governance efforts, as they publish rules, regulations, collective agreements with trade unions and codes of conduct through offline and online channels (Yu et al., 2025). Such information would usually serve as formal guidelines for their organizations’ modus operandi. They also shed light on how the businesses are directed and controlled among internal and external stakeholders. Ultimately, it is in the organizations’ interest to build stakeholder relationships and to maintain open lines of communication with different parties, including with creditors, investors, shareholders, employees, customers, suppliers, regulatory institutions and with local communities, among others.

There is scope for hospitality businesses to report about governance aspects including details about their organizations’ standards of integrity, accountability, board structure, executive compensation, and shareholder rights among other matters in their ESG reports. Such disclosures would probably make also reference to their businesses’ ethical dispositions as well as to risk management practices (e.g. compliance with health and safety, security issues, financial and operational aspects, reputation management, etc.) as these issues can help them build brand equity, instill trust in their activities and enhance their corporate reputation.

Specific disclosures about governance matters related to responsible food production and responsible consumption may include reference to accountable and transparent leadership that prioritizes the prevention of food loss and waste. The higher echelons of the organization ought to implement clear policies and procedures that ensure sustainable supply chain management. They are expected to monitor responsible food and beverage operations, at all times, from the procurement stage, through food preparation and consumption, in order to reduce food loss and waste. Food and beverage service providers ought to comply with relevant national legislation (where they operate their business) as well as with food safety and hygiene standards to protect their consumers’ health and wellbeing. They should handle, prepare and store their food and its components, in clean environments, to minimize spoilage, contamination and waste. This argumentation is congruent with substantive legislative instruments that are present in different jurisdictions, which require restaurants, among other entities, to implement sustainable measures that improve resource efficiency and prevent the generation of waste (EU, 2023a, GovUK, 2024, NEA, 2024).

A number of regulatory standards encourage practitioners to utilize food labeling that feature expiration dates (as well as nutrition information), to reduce food loss (Clodoveo et al., 2022). They may establish dedicated committees or sustainability champions to lead responsible food and beverage operations and initiatives that are intended to achieve continuous improvements in preventative and mitigative measures that reduce waste generated from hospitality businesses. Such practices may require ongoing training and development of employees on food and beverage practices like offering reduced portions and implementing efficient inventory management, to minimize food waste as much as possible.

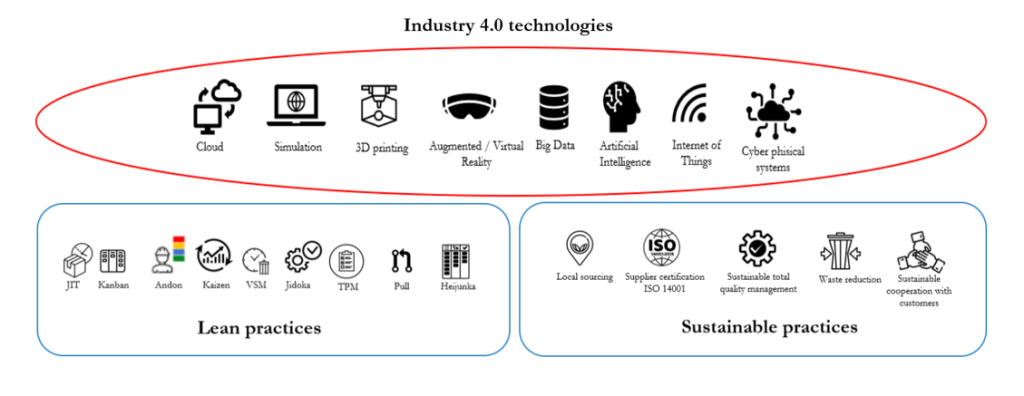

Hospitality businesses may refer to the industry standards (that are duly mentioned in this paper), and they can even obtain certifications from some of them, including Green Key Certification, International Standards Organization’s ISO 14001: Environmental Management Systems (EMS), among others, to improve their sustainability credentials for their food and beverage operations. These regulatory instruments can play a critical role in fostering ESG accounting, reporting, auditing and assurance. Fig. 1 clearly illustrates key elements that can be disclosed in ESG reports.

Fig. 1. The environmental, social and governance (ESG) dimensions (Camilleri & Carroll, 2024).

Regulatory instruments including standards and metrics for ESG reporting

Currently, several governments and intergovernmental institutions are encouraging big businesses to report information about their environmental, social and governance performance, in addition to their financial statements. Many of them are developing rules, regulations and guiding principles for corporations and listed enterprises. With regards to the materiality of their disclosures, report preparers need to take into account pertinent information (in terms of the reliability and completeness of the content they feature in their ESG reports) including on aspects related to critical issues related to sourcing of food and its ingredients, inventory management, preparation of meals (such as hygiene standards, use of local and organic ingredients), as well as other relevant details about measures that were undertaken to reduce food loss and waste. Hospitality businesses are expected to be transparent in their disclosures, to track progress vis-a-vis their efforts to reduce waste (year after year), and to identify areas that should be improved. Their ESG disclosures could also link food loss reduction initiatives with broader sustainability and financial performance metrics. This could enable them to evaluate their social, economic and environmental impacts of responsible food and beverage operations, and to develop comprehensive strategies and courses of action, for the future, to address their deficits.

Large entities, including hospitality chains as well as international food and beverage franchises, are usually expected by their stakeholders to prepare non-financial reports about their ESG performance in accordance with certifiable standards and/or eco-labels. They are bound to comply with relevant legislation about sustainability accounting, disclosures, audit and assurance practices applicable in specific jurisdictions where they operate their business,

For example, the European Union’s (EU’s) Non-Financial Reporting Directive (NFRD) Directive 2014/95/EU was one of the regulatory instruments that encouraged large undertakings to disclose non-financial information relating to ESG matters in their annual reports. Subsequently, the European Union built on the foundations of NFRD when it launched its Corporate Sustainability Reporting Directive (CSRD). Arguably, the latter directive has improved the harmonization and standardization of ESG disclosures (across the EU), in terms of their transparency, consistency, comparability and reliability aspects. While the NFRD was primarily focused on large public-interest entities (PIEs), the CSRD has extended reporting obligations to more companies, including large private companies and subsidiaries of non-EU parent companies operating within the EU member states (EU, 2023b). Business practitioners, including hospitality firms are encouraged to utilize renowned international standards to prepare their ESG disclosures. They may refer to Global Reporting Initiative’s (GRI’s) and/or to the Sustainability Accounting Standards Board’s (SASB’s) standards, among others. Whilst the former was not specifically designed to disclose information about food and beverage operations, GRI’s principles can still be applied in the hospitality industry sector.

Organizations could utilize the Global Reporting Initiative’s (GRI’s) guidelines to prepare non-financial reports that shed light on their ESG initiatives (Koseoglu et al., 2021, Li et al., 2025). They could refer to GRI’s Standards that are intended to support organizations in various aspects of their operations. Several GRI standards and guidelines can be used to address and reduce food loss and food waste in hotels and restaurants. While GRI does not have a specific standard solely focused on food waste, various standards cover aspects related to sustainability, waste management, and social responsibility that can be applied in this context. GRI has formulated topic standards related to the management approach (GRI 103 2016), procurement practices (GRI 204 2016), waste (GRI 306 2020), supplier environmental assessment (GRI 308 2016), labor/management relations (GRI 402 2016), occupational health and safety (GRI 403 2018), training and education (GRI 404 2016), marketing and labeling (GRI 417 2016): among others, that could be used to assess the businesses’ credentials, with regards to their responsible production and sustainable consumption of food.

Key takeaways

The underlying rationale behind this contribution is to promote responsible food and beverage operations within the hospitality industry. The sustainable sourcing of food products and their ingredients, their sound inventory management and control, the responsible preparation, production and consumption of food, can ultimately lead to a reduction in food loss and waste in hospitality settings including from hotels, restaurants and cafes, among others. The good practices that were mentioned in this article clearly address the environmental impact as well as social and economic dimensions, thereby promoting a holistic approach for the sustainability of food and beverage service providers.

This research raises awareness on the significance of non-financial accountability standards in the hospitality industry context. It makes reference to some of the most popular regulatory instruments and standards, including those set by the GRI, SASB and FLW among others, to promote ESG disclosures in corporate sustainability reports. Indeed, practitioners can utilize the standards mentioned in this paper, to account, measure and disclose their ESG performance. Arguably, such standards are instrumental to provide stakeholders with the necessary information to trace, evaluate and compare the sustainability efforts of hospitality firms.

This contribution builds on previous research that identified laudable food and beverage operations in the hospitality industry’s value chain; from the procurement of resources required for food production, leading to the point when surplus food and leftover items are reused, recycled or upcycled. It clarifies that excessive, edible and unspoilt food could be donated to food banks and/or to those in need, or even sold at discounted pricing through sharing economy platforms. Moreover, it also indicates that inedible foods can be converted into sustainable resources like garden compost or could be transformed into biogases, including methane (through anaerobic digester systems), that may be utilized for different purposes.

This research identifies and explains several ESG dimensions associated with food and beverage operations. It sheds light on several regulatory instruments comprising principles and standards, that may be adopted by practitioners to guide them in their ESG disclosures of their sustainable initiatives. Notwithstanding, this article puts forward a novel theoretical model that illustrates various responsible practices related to each of three (3) ESG dimensions. It clearly indicates that the hospitality businesses’ kitchen behaviors can be measured and accounted for in ESG reports, to provide stakeholders with a true and fair view of their sustainability credentials.

Future research directions

There is scope for further research focused on the main themes of this contribution. Academic colleagues may conduct primary research activities to explore the hospitality practitioners’ good practices, or lack thereof. They may reveal how they are planning, organizing, implementing and measuring the effectiveness of their responsible value chain activities. Prospective researchers may avail themselves of various methodologies and sampling frames, to explore this topic in depth and breadth. They could identify specific organizations including sustainability champions, that have a proven track record in: (i) reducing materials and resources, as well as in reusing and recycling surplus or leftover foods; (ii) utilizing sharing economy platforms and mobile apps to sell surplus foods at discounted prices; (iii) donating food to community projects; and/or iv) recycling inedible foods for compost purposes, among other options.

New submissions to journals could promote the positive multiplier effects of engaging in responsible food and beverage operations in terms of operational efficiencies and cost savings, improved corporate image and reputation, and the like. They could raise awareness on the business case for responsible food production and consumption behaviors. Alternatively, future researchers could prepare theoretical and/or discursive papers that clearly explain how, where, when and why hospitality firms are accounting their sustainable ESG activities. They may refer to specific standards and metrics presented in this article.

In addition, they may prepare comparative analyses of different ESG reporting frameworks (e.g., GRI and SASB among others). Their research might reveal the strengths and weaknesses of each framework and could possibly evaluate their standards and metrics in detail. Scholars could explore the enablers and barriers associated with ESG accounting, reporting, auditing, and assurance. They may focus on organizational aspects, financial and technological issues, regulatory interventions, and/or on cultural influences that could either support or hinder the widespread adoption of sustainable food and beverage initiatives in the hospitality sector.

Suggested citation: Camilleri, M. A. (2025). Sustainability accounting and disclosures of responsible restaurant practices in environmental, social and governance (ESG) reports. International Journal of Hospitality Management, 126, https://doi.org/10.1016/j.ijhm.2024.104051

You must be logged in to post a comment.